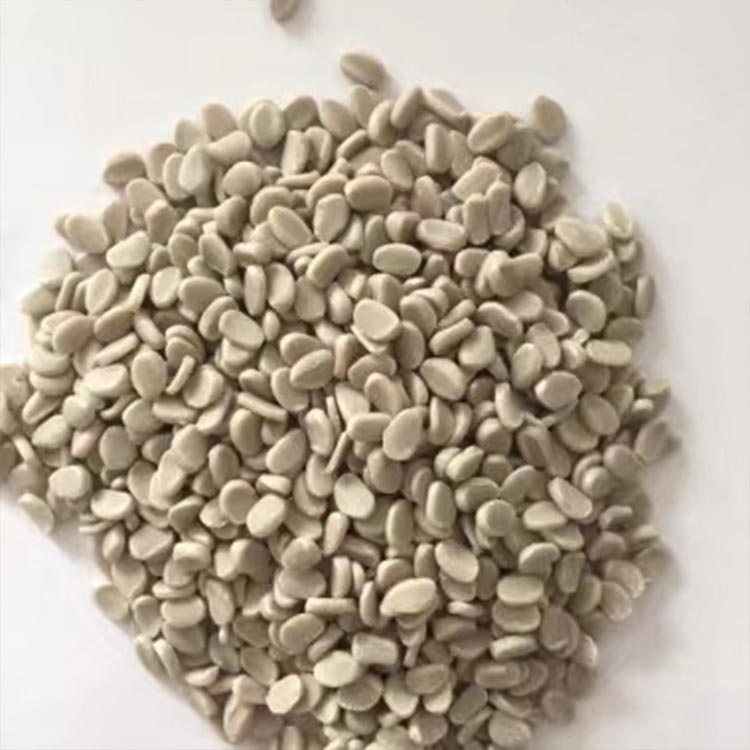

防潮消泡母粒

防潮消泡母粒是一种化学助剂,它具有防潮、消泡的双重功效,可以在很多工业领域中使用。

一、防潮消泡母粒的定义

防潮消泡母粒是一种特殊的化学混合物,通常由多种化学物质组成,包括聚合物、表面活性剂、抗氧化剂和稳定剂等。它主要用于防潮和消泡的作用,并可以在各种材料和物质中进行挥发和控制。

二、防潮消泡母粒的性能

防潮消泡母粒具有多种性能,包括但不限于以下几点:

1.防潮功能:防潮消泡母粒能够控制水分的进出,从而防止水分对材料的影响。

2.消泡功能:防潮消泡母粒可以降低气泡生成和堆积的速度,从而避免出现过多泡沫对工业生产的影响。这种功能对于各种液体或半液体的制造、加工和包装都具有很大的价值。

3.稳定性:防潮消泡母粒具有良好的稳定性,可以在各种温度和湿度下保持其性能。这种稳定性能够给使用者带来很大的便利,特别是在一些恶劣的环境条件下仍然能够发挥作用。

4.耐热性:防潮消泡母粒能够承受高温环境,即使在一些高温加工过程中也能够保持其性能。这使其在工业生产中应用更加广泛。

三、防潮消泡母粒的应用

防潮消泡母粒具有广泛的应用领域,包括但不限于以下几个方面:

1.医药行业:防潮消泡母粒可以在医药行业的生产和包装过程中发挥作用,防止药品遇潮或者生成气泡。

2.塑料制造:防潮消泡母粒可以在塑料制造中发挥作用,防止水分进入塑料中,从而防止其变质或者产生瑕疵。

3..涂料、油漆:防潮消泡母粒可以在涂料和油漆的生产和使用过程中发挥作用,控制气泡和泡沫的生成,提高涂层的质量。

Anti-foaming masterbatch is a kind of chemical additives, it has the double effect of anti-moisture and defoaming, and can be used in many industrial fields.

I. Definition of Anti-foaming Masterbatch

Anti-foaming masterbatch is a special chemical mixture, usually composed of a variety of chemicals, including polymers, surfactants, antioxidants and stabilizers. It is mainly used for moisture-proof and defoaming effect, and can be volatilized and controlled in various materials and substances.

Anti-moisture defoaming masterbatch

Performance of antifoaming masterbatch

Anti-moisture defoaming masterbatch has a variety of properties, including but not limited to the following points:

1. Moisture-proof function: moisture-proof defoaming masterbatch can control the in and out of moisture, so as to prevent the impact of moisture on the material.

2. Anti-foaming function: Anti-moisture defoaming masterbatch can reduce the speed of bubble generation and accumulation, thus avoiding the impact of excessive foam on industrial production. This function is of great value for the manufacture, processing and packaging of various liquids or semi-liquids.

3. Stability: moisture defoaming masterbatch has good stability, can be in a variety of temperature and humidity to maintain its performance. This stability can bring great convenience to users, especially in some harsh environmental conditions can still play a role.

4. Heat resistance: moisture defoaming masterbatch can withstand high-temperature environments, even in some high-temperature processing can maintain its performance. This makes it more widely used in industrial production.

Third, the application of moisture-proof defoaming masterbatch

Anti-foaming masterbatch has a wide range of applications, including but not limited to the following aspects:

1. Pharmaceutical industry: Anti-foaming masterbatch can play a role in the production and packaging process of the pharmaceutical industry, to prevent the drugs from moisture or generate air bubbles.

2. Plastic manufacturing: Anti-foaming masterbatch can play a role in plastic manufacturing, preventing moisture from entering the plastic, thus preventing it from deteriorating or producing defects.

3.. Coatings and paints: Anti-foaming masterbatch can play a role in the production and use of coatings and paints to control the generation of bubbles and foam and improve the quality of the coating.